STARTING WITH THE "ENGINEERING AND PRODUCING WITH ADDITIVE MANUFACTURING 3D PRINTING" UNIVERSITY DIPLOMAUniversity diploma

Additive manufacturing has developed in many companies in many industrial sectors such as aeronautics and health, due to its interest in innovating products and processes.

However, companies are currently seeking executives or specialists capable of controlling the whole additive manufacturing value chain (meaning materials to applications, controlling chemical risks, design and the logistics supply chain).

These specialists must be able to address problems beforehand (with the material) and after (with the product) through the value chain, and even to anticipate wherever possible. These employees must have a global overview of all the steps and not solely regarding the machine as is the case today.

WHAT IS AN EXPERT IN THE ADDITIVE MANUFACTURING CHAIN - 3D PRINTING?

It is a specialist with a transversal approach, from the raw material to the finished product that companies are looking for. They bring the company the expertise needed in material qualification (raw material and analyses of products’ use properties), in industrial engineering for the safety, quality and regulatory aspects of additive manufacturing.

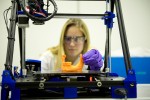

Additive manufacturing is defined in the standard NF EN ISO/ASTM 52900 as : "A process of assembling materials to manufacture parts from 3D model data, usually layer by layer, unlike subtractive and shaped manufacturing methods.”

OBJECTIVES

Toulouse INP-ENSIACET has such a transversal approach, from the raw material to the finished product, which is what companies are looking for.

The university diploma in Engineering and producing with additive manufacturing - 3D printing offered at our graduate engineering school must bring expertise into the sector needed in:

- Material qualification (raw material and analyses of products’ use properties),

- Industrial engineering,

- Aspects regarding safety/quality,

- Regulatory aspects of additive manufacturing.

This new curriculum caters for new emerging professions. It is intended for employees or jobseekers wishing to gain skills, willing to try something new, capable of adapting to a new field of work: being proficient in concepts associated with additive manufacturing/3D printing.

This curriculum enables the students to develop further use of additive manufacturing with a global vision over the manufacturing line, be it as the workshop or design office coordinator.

It also provides the opportunity to train specialists in additive manufacturing engineering with an integrated approach, capable of:

- Managing the additive manufacturing chain and solution-finding (set-up, control and handling),

- Developing strategies for building parts, seeking the best machine parameters according to type of materials,

- Monitoring technology, setting up research and tests, defining the necessary tools, simulating, testing and analyzing the results.

RELEVANT PUBLIC

Lifelong training, professional training, work-study program...

COURSE SCHEDULE

With a work-study program there are 2-5 weeks of lessons per month totaling 385 hours of classes and 27 weeks of work placement.

ADMISSIONS

This training is particularly adapted to professionals seeking to change careers:

- employees,

- jobseekers,

- under 26-year-olds who wish to complete their initial training after a undergraduate degree or Master’s degree in material or mechanical engineering.

REQUIREMENTS

- 2-year technical degree (DUT in physical measures, mechanical and production engineering, chemical engineering, process engineering, materials engineering, engineering in chemistry or industrial engineering or equivalent course) with a minimum of 3 years’ professional experience in the field.

- 3-year technical undergraduate degree (in mechanics, materials engineering, chemical engineering, process engineering or industrial engineering).

- Master’s level (scientific or general engineering Master’s degree).

- Skills in 3D CAD is required for all candidates regardless of their qualification.

ADMISSIONS PROCEDURE

- Initial selection based on application.

- Interview.

APPLICATIONS

- The application form is to be downloaded from www.fc.inp-toulouse.fr and to be sent back by 10 June 2019.

- The chosen candidates will be invited to an interview in June.

PROGRAM

MATERIALS AND ADDITIVE MANUFACTURING TECHNOLOGY (70 HRS)

- Additive Manufacturing technology

- Classes of materials (Metals, polymers, ceramics)

- CAD and the digital chain

RULES/NORMS/SAFETY/QUALITY (70 HRS)

- Rules and safety

- Norms and quality

INTEGRATED DESIGN AND SUPPLY CHAIN LOGISTICS (70 HRS)

- Tools and sequencing

- Manufacturing range

- Logistics

- Integrated Conception costs

- Information technology and ERP

QUALIFICATION OF PARTS AND RAW MATERIALS (105 HRS)

- Statistical control of processes

- Procurement, manufacturing and testing specifications

- Raw material control (technical / practical aspects)

- PLM stage control (of products (technical / practical aspects)

- Powder, process, part, environment qualification costs

- Operational costs

SPECIALIZATION IN AERONAUTICS AND THE MEDICAL SECTOR (70 HRS)

- Additive manufacturing in the space and aeronautics industry

- Additive manufacturing in the medical industry

STUDY PROJECT (DONE THROUGHOUT THE YEAR)

JOB OPPORTUNITIES

- Industrial production executive (Workshop manager, mechatronics engineer etc.)

- R&D executive

- Head controller

- Design engineer

- Additive manufacturing integration specialist